What are the three types of punches

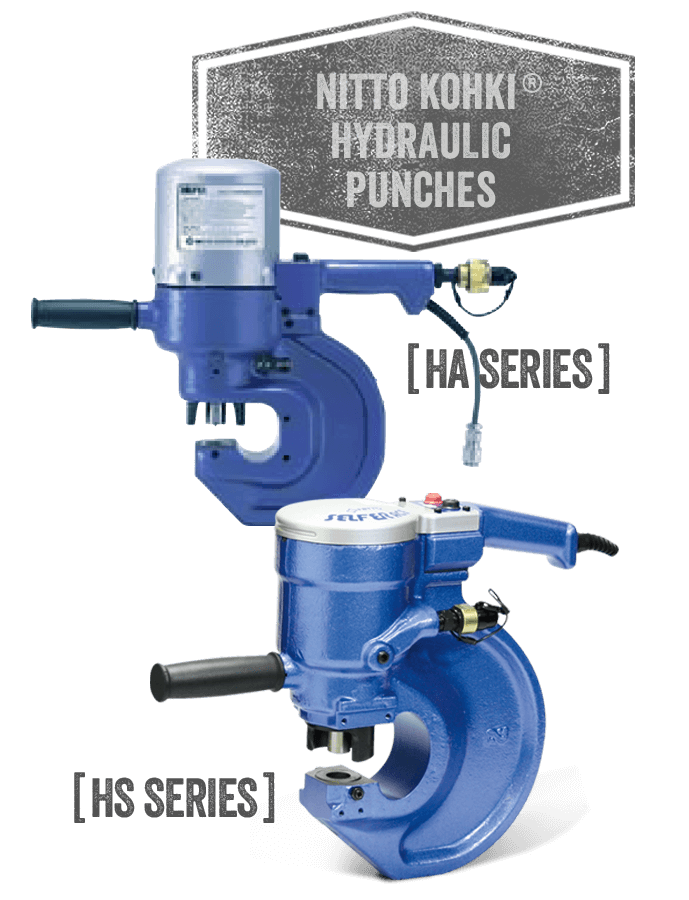

Hydraulic punches, aside from their compact size, offer great versatility and a stunning throat depth.

The machine has a dual-action design that reduces cycle time. It also allows for minimal material handling which results in highly efficient holes when compared to other processes.